How panel PCs are helping food producers meet their sustainability goals

Cranswick is a leading sustainable British food producer. Its simple mantra of “Good in equals good out” has led to them becoming one of the largest fresh food producers in Britain. With state-of-the-art production facilities and a vision to become the world’s most sustainable meat business, Cranswick’s focus on quality, efficiency and sustainability runs all the way through its supply chain from farm to fork.

Its Gourmet Sausage site, Lazenby’s in Hull, is often used as a pilot site for a range of new innovations and tech. So, it was no surprise that it was chosen as a test bed for a new system designed to build on the already high standards of compliance, productivity and environmental stewardship.

Sam Wilkinson, IT Team Leader, Cranswick Country Foods, said: “As a company, we are passionate about producing the best quality food, efficiently and sustainably, in well invested facilities across the UK. Technology is revolutionising sustainability and we are keen to implement digital solutions and push technology further to support our vision.”

The challenge

Cranswick is committed to validating and verifying the safety of raw materials and the food production process. The manufacturing sites rigorously enforce this through multiple compliance check points to ensure that the food products are safe, legal, and of the quality specified by customers.

Declan Stringer, Cranswick’s Head of IT Operations and Projects, said: “This process relies on the manufacturing team completing multiple paper records and transferring them onto spreadsheets which could be prone to human error and increases paper consumption within the company. As part of Cranswick’s Second Nature sustainability strategy, we want to move away from paper usage and systemise our processes.”

The solution

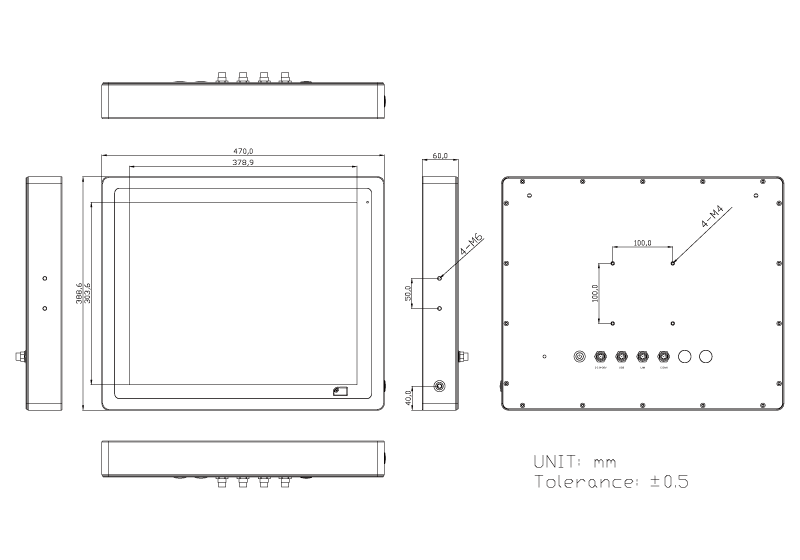

The Lazenby’s site chose to implement DSL’s fully IP66/69K rated stainless steel panel PCs in various sizes across their food production environment – the installation environment is exactly the environment the systems are designed to be used in.

The ViTAM series features a wide range of platforms from Intel Atom, 6th Gen. Core i to ARM based, and comes in displays and panel PCs. It is packed with the most popular expansion modules for industrial market and features a full range of panel sizes from 10.1” to 24”. With vandal-proof hardened glass for ultimate durability, high brightness LCD, and -20°c / 60°c operation, they can also handle high pressure steam jet cleaning which is ideal for the food production environment.

Declan adds: “We’ve tried other solutions but they have been clunky stainless-steel boxes. The DSL panel PCs are contained within one unit; sleek and compact, with good functionality. They will enable us to capture, access and report actionable data in real-time, and avoid repetitive data collection.

“This is something I see being replicated across the entire business in the future – it’s a stepping stone to the further use of technology to streamline and systemise our processes for the good of our customers and the planet.”

The result

Sam says: “The system has been transformative. It has simplified our production process, saved time, reduced food waste and eliminated paper usage. The panel PCs are easy to clean which is crucial and withstand being hosed down multiple times a day. All the information is now electronically stored which is essential for compliance and we can quickly and easily track every single product at every stage of the process – from farm to fork – to ensure our gourmet sausages are bang on!”.

Sam added: “As with any pilot project, it is not unexpected to have challenges along the way. The team were a little apprehensive about a new technological system replacing the old paper process, but with training and seeing the benefits for themselves, any concerns were quickly overcome.

“We also had the odd niggle with the device drivers. DSL immediately came to site to find the problem and new firmware resolved the issue. Rory and the team are always on hand to advise and support. How companies deal with after-sales support is a key indication of the quality and commitment of the business, and DSL’s exceptionally high-level of customer support speaks volumes.”

Looking to the future

Sam says that Cranswick advocates working with Britain’s SMEs: “I would definitely recommend DSL for quality and service. It’s great to work with a customer-centric, UK-based SME which embodies collaboration and value; our relationship will be long-term and mutually beneficial.”

Rory Dear, Managing Director, DSL, adds: “Cranswick is a hugely important client and they have used a large number of our systems over the last few years.

“We particularly enjoy working with Cranswick and value their patience and willingness to work with us in such a collaborative way, particularly throughout the challenges of visiting and keeping in touch during COVID-19.

“They have excellent in-house IT expertise headed up by Declan and Sam who are knowledgeable, understanding and a pleasure to work with. Our relationship is open and responsive on both sides and it really feels like we are part of one big team.”

Cranswick is now in the process of rolling out DSL’s panel PCs to other factories across the business and the DSL team continue to be on-hand to support the (sausage!) roll out.

Click on the links for more information about Cranswick’s sustainability strategy, Second Nature, and DSL’s stainless steel fully IP rated panel PCs.